Understdand Optical Silicone

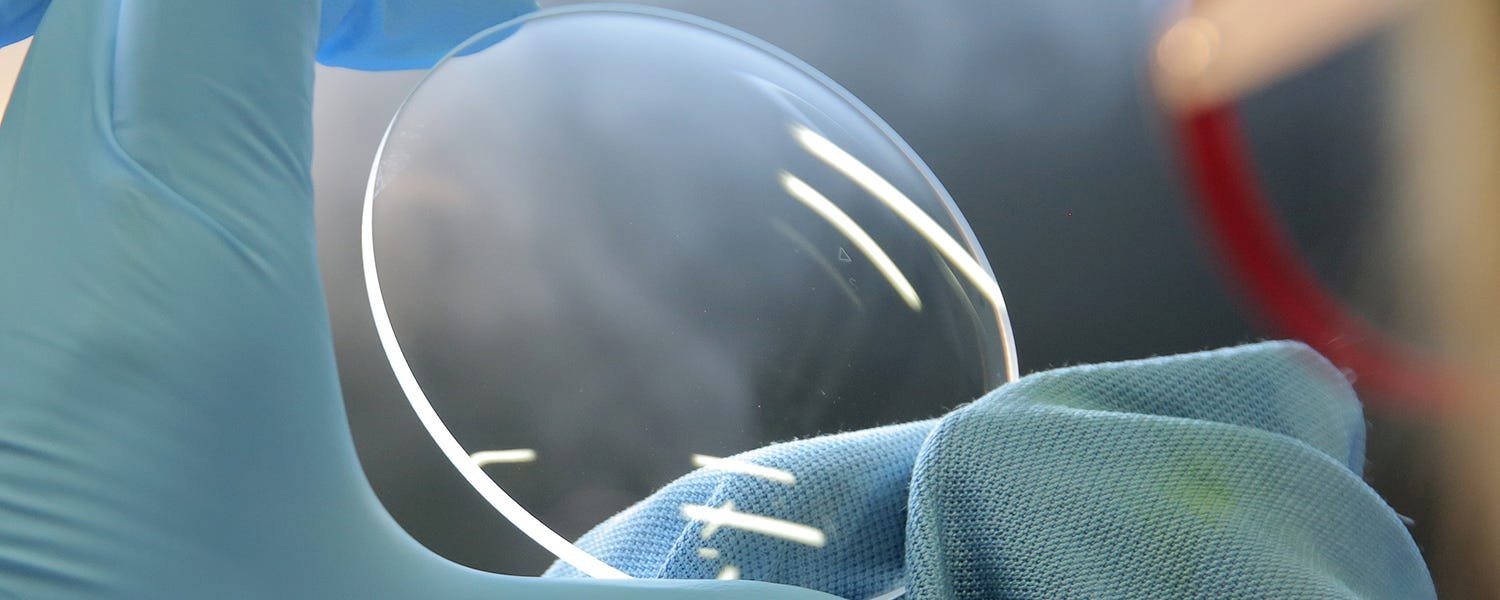

What is optical silicone?

Optical silicone is a specialized silicone elastomer engineered for optical clarity, precision molding, and long-term stability. Specifically designed for optical applications, it features high transparency, minimal yellowing, and excellent thermal and UV resistance, making it ideal for lenses, LED encapsulation, optical fibers, and precision optical components.

Key Characteristics of Optical Silicone

- High Optical Clarity: Excellent transparency with minimal distortion.

- Stable Refractive Index: Ensures consistent optical performance.

- UV and Thermal Resistance: Maintains clarity without yellowing or degradation.

- Low Shrinkage: Provides precision dimensional stability after curing.

- Flexibility & Durability: Resists mechanical stress, impacts, and vibration.

- Excellent Weatherability: Performs reliably under harsh environmental conditions.

- Low Viscosity: Enables precise molding and detailed encapsulation.

- Chemical Stability: Resistant to moisture, ozone, and environmental aging.

Types of Optical Silicone Rubber

Typical High Tranparency Liquid Silicone Rubber For Injection Molding

Refractive index 1.41, Light transmittance 94%. This types of product is design for producing high transparency silicone products. Which take up most of the optical silicone market.

Phenylsiloxane-based Silicone Rubber for Injection Molding

RI 1.46, light transmittance 93%. This types of product is design for producing screen film on eletronic device screen. And this product own the property of higher elastisity as elastomer. But due to the limited appliciton, this product is the rarest optical silicone in market.

LED encapsulation material

RI 1.52, light transmittance 95%. This types of product is design LED encapsulation. High proportion of Phenylsiloxane resin to ensure high fluidity and easy dispensing. Can be used on application of LED encapsulation and protection, discrete lenses for LEDs and optical components, high-purity electronic and optical applications.

How to Test Optical Level?

Two key factors: Light Transmittance and Refractive Index.

1. Light Transmittance Testing

- Method: Using a spectrophotometer (according to ASTM D1003 standard).

- Procedure: Measure the percentage (%) of light transmitted through a cured silicone sample at specific wavelengths (typically visible spectrum: 380-780 nm).

- Purpose: To quantify the transparency and clarity of silicone.

2. Refractive Index Measurement

- Method: Typically measured using an Abbe refractometer or automatic refractometer (ASTM D542 standard).

- Process: Measures how much the silicone bends (refracts) a beam of light.

- Purpose: To verify consistency in optical properties crucial for precision optical applications.

Supplier and Typical Model of Optical Silicone Rubber

Most of liquid silicone rubber supplier can product RI 1.41 high transparency silicone material, let us focus on Higher RI products.

LED Encapsulation Silicone

Dupunt Duroptix™ OE-6650 A/B:

100% Transmissivity at 450 (nm/1mm), Refractive Index 1.54, Mixing Ratio: 1:3

DuPont silicone LED (light emitting diode) encapsulants are designed to meet the challenging needs of the LED market, including high adhesion, high purity, moisture resistance, thermal stability and optical transmittance. Silicone materials can absorb stresses caused by thermal cycling inside the package, protecting the chip and the bonding wires.

Shin-Etsu’s ASP-2010

90% Light Transmissivity (400nm/2mm), Refractive Index 1.57 (23C/589nm), Mixing Ratio: 1:4

Shin-Etsu’s ASP-2010 A/B is a dual component, heat cure LED potting encapsulant that is designed for use in conjunction with Shin-Etsu’s KER-2000 DAM/KER-2020 DAM damming materials for LED and COB applications. ASP-2010 A/B is a phenyl-based, hybrid technology which allows for an exceptional refractive index.

LUMISIL® 585 S

90% Light Transmissivity (450nm/1mm)450 nm, Refractive Index 1.54, Mixing Ratio: 1:8

The silicone specialist WACKER has extended its LUMISIL® product portfolio to meet the challenging requirements of leading LED manufacturers. The LUMISIL® name stands for high-performance optical-grade silicones with impressive characteristics

Phenylsiloxane-based Silicone Rubber for Injection Molding/RI 1.46

Phenylsiloxane-based Silicone Rubber for Injection Molding

Nusil LS-6946

93% Light Transmissivity (450nm/1mm), Refractive Index 1.46 (589nm), Mixing Ratio: 1:1

The product is supplied in a ready-to-use cartridge that allows off-line mixing in a preset 1:1 ratio, prior to casting or loading into an injection molder reservoir.

Our Brand and Model

In addition to standard liquid silicone materials with a refractive index (RI) of 1.41, we have developed and introduced two specialized models to meet the demands of high-end LED applications. One is specifically designed for injection molding, while the other is tailored for LED encapsulation silicone products.

CAS-TD50A/B LED Encapsulation Silicone

95% Light Transmissivity (450nm), Refractive Index 1.51, Mixing Ratio: 1:10

CAS-TD50A/B is a two-part, high proportion of phenylsiloxane resin silicone material designed for high-performance LED and optical applications. Offers excellent thermal stability, moisture resistance, and optical clarity.

CAS-TA40A/B High RI for Injection Molding

93% Light Transmissivity (450nm), Refractive Index 1.46, Mixing Ratio: 1:1

CAS-TA40A/B is a two-part, phenylsiloxane-based silicone material ideal for high-performance LED and optical applications. It provides excellent thermal stability, moisture resistance, and optical clarity, making it suitable for injection molding.