Flame Retardant Solid Silicone Rubber GA-8961

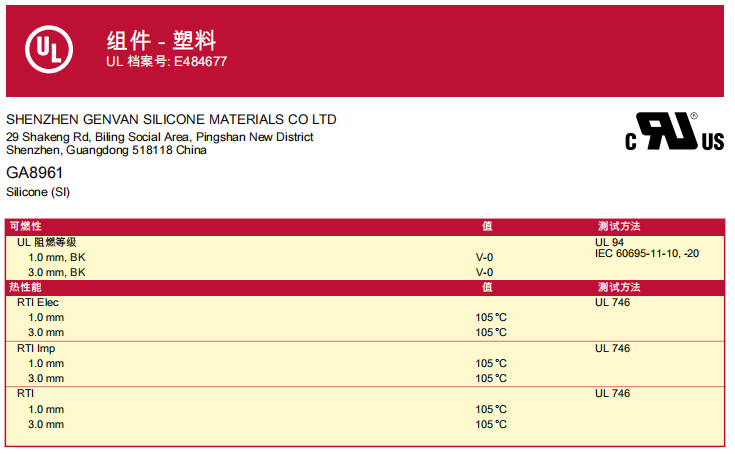

1mm UL94-0, Halogen-free flame retardant

GA-8961 is a two-component, semi-transparent silicone rubber that utilizes platinum catalyst or DCBP as the curing agent. This versatile silicone material is specifically designed for applications requiring excellent flame resistance. It is commonly used in industries such as electrical cables, automotive spare parts, and gaskets, providing reliable protection and durability in high-temperature and fire-prone environments.

Technical Index

| Uncure property | |

| Appearance | Milk white |

| Plasticity | 320 |

| Curing property (120℃ curing 10min, 120℃ bake 1H) | |

| DCBP proportion | 1.2% |

| Mechanical property | |

| Density (25℃) g/cm 3 | 1.22 |

| Hardness (A) | 63 |

| Tensile strength MPa | 10.2 |

| Elongation % | 370 |

| Tearing strength KM/m | 36 |

| Heat resistance property (250℃/72H) | |

| Hardness change | +2 |

| Tensile strength change % | -13 |

| Elongation change % | -27 |

Storage condition:

- store in a cool,dry and ventilated place;

- circumstance temperature must be under 30℃ Expiration date:6 months.

Packing specification: 20KG/box.

Use Direction of Flame Retardant Solid Silicone Rubber 8961

To use GA-8961, mix the curing agent according to the specified mix ratio.

Ensure the mixing mill is clean before use. Process the rubber using a double roller mill until smooth edges and surfaces are formed.

Once the silicone (with curing agent) is fully mixed, use it as soon as possible. Prolonged storage after mixing may cause it to cure prematurely and lose its effectiveness.

Handling Precautions for Flame Retardant Solid Silicone Rubber 8961

If the fully mixed rubber has been stored for a long period, it may be remixed for use. However, its properties should be inspected to ensure it still meets performance standards.

Always operate in a well-ventilated area to ensure safety during handling.

Storage of Flame Retardant Solid Silicone Rubber 8961

Store the GA-8961 in a cool, dry, and well-ventilated place, ensuring that the environmental temperature is below 30°C (86°F). Proper storage is essential to maintain the quality and effectiveness of the silicone rubber.