Silicone leather is rapidly emerging as a groundbreaking material, fundamentally redefining what’s possible in sustainable design. This innovative fabric perfectly blends advanced performance with a strong environmental ethos. Unlike traditional alternatives like PVC or PU, silicone leather offers exceptional durability, softness, and stain resistance, all while being a non-toxic and eco-friendly choice. Its versatility allows it to seamlessly integrate into various industries, making it a pivotal component in creating products that are both high-quality and environmentally responsible.

What is Silicone Leather?

Silicone leather is an innovative, high-performance material. It serves as a superior alternative to traditional animal leather and conventional synthetic leathers like PU (polyurethane) and PVC (polyvinyl chloride). It’s fundamentally composed of silicone polymers applied onto a fabric backing, typically woven or non-woven textiles. This unique composition gives it a distinct set of advantageous properties. It is inherently vegan and designed with sustainability in mind. Silicone leather offers a premium look and feel. It delivers exceptional durability and performance, making it a modern choice for various applications.

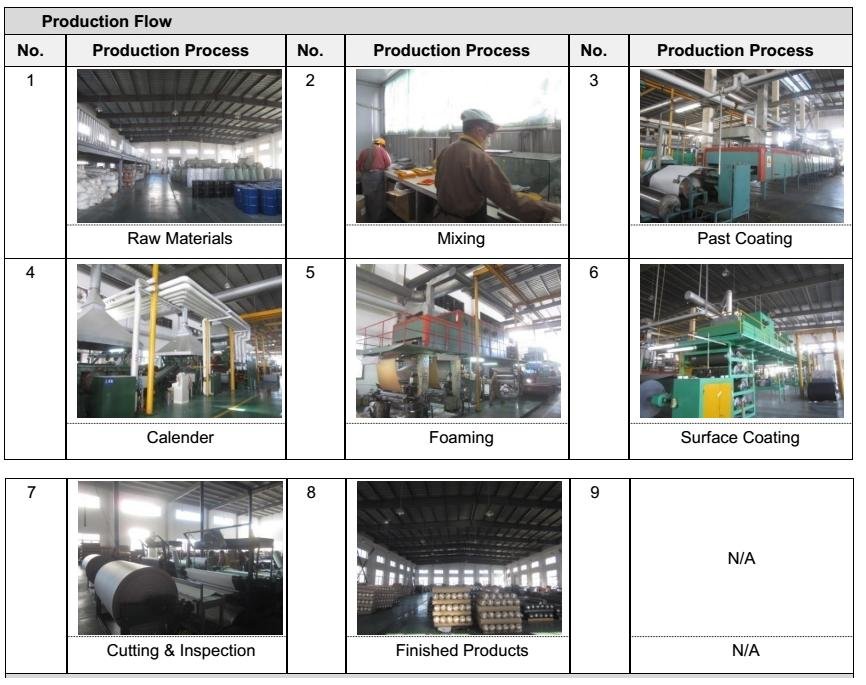

How Silicone Leather is Made

The manufacturing process for silicone leather is typically cleaner and more environmentally friendly than that of many other synthetic leathers. It generally involves a multi-step coating and curing process:

Material:

- Liquid Silicone Rubber (LSR): The primary silicone component.

- Organohydrogen Polysiloxane: Acts as a crosslinking agent to facilitate the silicone’s curing.

- Platinum Catalyst: Initiates and accelerates the curing reaction at specific temperatures.

- Adhesion Promoter: Contains an alkoxysilane compound. This is crucial for achieving direct bonding.

- Fiber Substrate: A fabric material such as polyester, nylon, cotton, or rayon (non-woven or knitted fabric).

Production Steps:

- 1. Preparation of Silicone Resin Composition:

- The Liquid Silicone Rubber (LSR) is thoroughly mixed with the organohydrogen polysiloxane, platinum catalyst, and the essential adhesion promoter (containing the alkoxysilane compound).

- All components are uniformly dispersed to create a viscous, coatable liquid silicone resin composition.

- 2. Preparation of Fiber Substrate:

- An appropriate fiber substrate (e.g., non-woven or knitted fabric made of polyester, nylon, cotton, or rayon) is selected.

- The substrate is prepared to ensure a clean surface, ready for the subsequent coating.

- 3.Silicone Coating:

- The prepared silicone resin composition is uniformly coated onto one surface of the fiber substrate.

- Various coating methods can be employed based on production equipment, including but not limited to:

- Knife coating

- Gravure coating

- Spray coating

- Comma coating

- The aim is to form a silicone resin layer with a thickness of 0.1 to 0.4 mm.

- 4.Silicone Layer Curing (Heat Treatment):

- The coated fiber substrate then moves into a heating zone for curing.

- The heating temperature is controlled between 100 and 160°C.

- The heating duration is 30 seconds to 5 minutes.

- During this stage, the silicone composition undergoes a crosslinking reaction, transforming from a liquid to a solid, elastic silicone layer that is firmly adhered to the fiber substrate.

This manufacturing method often results in lower VOC (Volatile Organic Compound) emissions. It also avoids the use of plasticizers, which are common in PVC and some PU leathers.

Key Benefits of Silicone Leather for Sustainable Design

Silicone leather offers compelling advantages that position it as a leader in sustainable design. Its unique composition and advanced manufacturing processes ensure both high performance and a reduced environmental footprint.

Its production boasts significantly cleaner chemistry. Unlike many synthetics, silicone leather is manufactured with lower VOC (Volatile Organic Compound) emissions and contains no harmful plasticizers like phthalates. Modern production methods also focus on efficiency, inherently minimizing waste and resource use compared to traditional processes.

This material excels in durability and longevity. Its inherent resistance to abrasion, tearing, UV radiation, and extreme temperatures means products made with silicone leather last longer. This extended lifespan directly contributes to sustainability by reducing the frequency of replacement and overall waste.

Furthermore, silicone itself is an inert, non-toxic, and biocompatible material, making it a safer choice throughout its life cycle. Its non-porous surface also ensures easy cleaning and low maintenance, reducing the need for harsh chemicals and prolonged care. These combined attributes make silicone leather a truly responsible and high-performance material for a sustainable future.

Silicone Leather vs. Traditional and Other Synthetic Leathers

Silicone leather stands out significantly when compared to traditional animal leather and other synthetic alternatives like PU and PVC.

| Feature | Silicone Leather | Animal Leather | PU Leather (Polyurethane) | PVC Leather (Polyvinyl Chloride) |

| Source | Synthetic (Silicone Polymer) | Animal Hides | Synthetic (Polyurethane coating on fabric) | Synthetic (PVC coating on fabric) |

| Vegan/Cruelty-Free | Yes | No | Yes (but often with plasticizers) | Yes (but significant environmental concerns) |

| Durability | Excellent. High resistance to abrasion, tears, flex. Long lifespan. | Good, but varies. Can crack, scuff, and absorb stains. | Good, but prone to peeling/cracking over time, especially with hydrolysis. | Fair to Good, but can become brittle and crack with age/UV. |

| Environmental Impact | Lower VOCs, no plasticizers, eco-friendly production. | High (tanning chemicals, water usage, methane). | Moderate (some VOCs, solvents often used). | High (phthalates, VOCs, chlorine, difficult to recycle). |

| Feel/Touch | Soft, smooth, often luxurious. | Varies (can be soft, supple). | Varies (can mimic leather well, but often feels more “plastic”). | Stiffer, less breathable, often feels more “plastic-like.” |

| Maintenance | Very easy to clean, stain-resistant. | Requires specialized cleaning/conditioning. | Easy to wipe clean, but stains can set. | Easy to wipe clean, but can absorb color from dyes. |

| Breathability | Can be engineered for breathability. | Natural breathability. | Generally lower breathability. | Very low breathability. |

| UV Resistance | Excellent. Resists fading and degradation. | Can fade and crack with prolonged sun exposure. | Prone to UV degradation and yellowing. | Prone to UV degradation and cracking. |

| Safety (Toxicity) | Non-toxic, bio-compatible. | Generally safe (after tanning process). | Can contain DMF or plasticizers (e.g., phthalates). | Often contains harmful phthalates and chlorine. |

Silicone leather consistently outperforms other options in terms of combining durability, aesthetic appeal, and a significantly reduced environmental footprint, making it a leading choice for the future of material design.

Applications of Silicone Faux Leather in Modern Design

The versatility and superior performance of silicone faux leather have led to its widespread adoption across various industries, making it a preferred material in modern design:

- Automotive Interiors: Its durability, UV resistance, easy cleanability, and non-toxic properties make it ideal for car seats, dashboards, door panels, and steering wheel covers. It offers a premium feel while withstanding extreme temperatures and heavy use.

- Contract & Residential Furniture: Silicone leather is increasingly used for sofas, chairs, benches, and headboards. Its stain resistance, scratch resistance, and luxurious soft touch make it perfect for high-traffic public spaces (hotels, restaurants) and homes, especially those with children or pets.

- Healthcare & Medical Environments: Its inherent biocompatibility, non-porous nature, and ability to withstand repeated cleaning with disinfectants make it an excellent choice for hospital beds, examination tables, waiting room seating, and medical device upholstery. It helps maintain hygienic environments.

- Marine & Outdoor Upholstery: With exceptional resistance to saltwater, UV radiation, mildew, and extreme weather, silicone leather is perfect for boat seating, outdoor patio furniture, and marine interiors. It ensures longevity and color stability in harsh conditions.

- Fashion & Accessories: Designers are incorporating silicone leather into handbags, wallets, shoes, and apparel. Its flexible nature, soft feel, and ability to be molded or textured offer creative possibilities for cruelty-free and durable fashion items.

- Hospitality & Public Spaces: Its robust performance, aesthetic appeal, and ease of maintenance make it suitable for hotel lobbies, restaurant booths, airport seating, and office furniture. It combines style with functional longevity.

Silicone faux leather’s adaptability enables designers to push boundaries, creating products that are not only beautiful and functional but also align with sustainable and ethical values.

Conclusion

Silicone leather is truly redefining sustainable design. This transformative material offers exceptional durability, superior performance, and a significantly reduced environmental footprint through cleaner manufacturing processes. Free from harmful plasticizers and minimizing waste, its inherent non-toxicity and versatility drive its rapid adoption across industries like automotive, furniture, and fashion. As demand for eco-friendly solutions grows, silicone leather is set to play a vital role in shaping a more sustainable future.