Optical grade silicone is transforming the optics industry. Its unique properties make it a preferred choice for many applications. This versatile material is known for its high light transmittance and durability. It increasingly replaces traditional materials like glass and polycarbonate, especially where flexibility, impact resistance, and complex molding are critical.

Engineers and designers are increasingly turning to optical grade silicone. It offers excellent flexibility. It can also be molded into intricate shapes. This makes it ideal for innovative optical components. Key evaluation dimensions for optical silicone include its transmittance and refractive index. These properties can be precisely controlled.

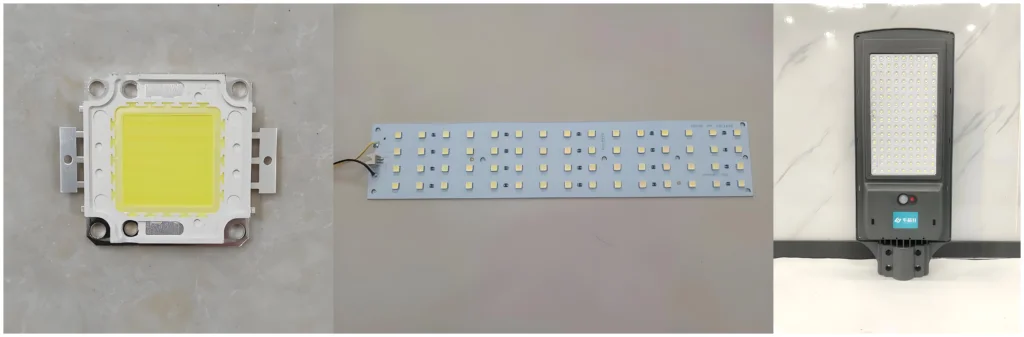

The material’s resistance to UV light and environmental factors ensures longevity. It’s widely used in LED lighting, automotive lighting, and medical devices. Its stability and clarity are unmatched. Future applications are also promising. Optical grade silicone will play a vital role in augmented reality (AR), virtual reality (VR), and advanced optical sensors.

Optical grade silicone’s adaptability is another key advantage. It can be customized for specific optical needs. This makes it a valuable asset in emerging technologies. In this article, we explore the benefits of optical grade silicone. We’ll delve into its properties, applications, and advantages. Discover why optical grade silicone is the future of optical materials.

What Is Optical Grade Silicone?

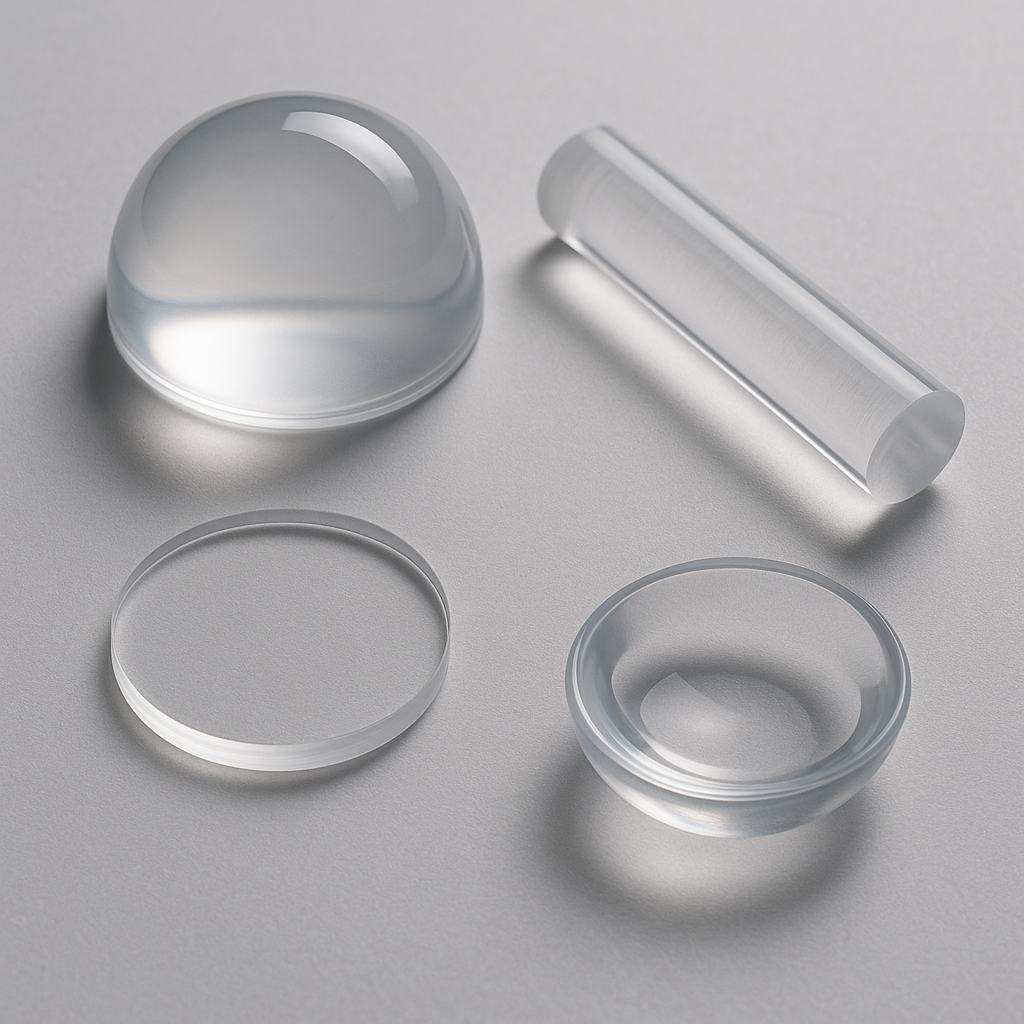

Optical silicone is a specialized form of silicone. It’s designed specifically for optical applications. This material combines high transparency with excellent physical properties. It’s specially formulated to meet stringent optical performance requirements. It often replaces traditional optical materials. These can include glass and polycarbonate.

The versatility of optical silicone allows its use in various forms. These include films, lenses, and light guides. This adaptability makes it integral in both standard and innovative optical applications.

How Optical Grade Silicone Replaces Traditional Optical Materials

Optical silicone is rapidly becoming the material of choice in optics, often outperforming and replacing traditional options like glass and polycarbonate (PC), as well as PMMA (acrylic). Its unique set of properties addresses many limitations of these older materials, driving innovation across various sectors.

Optical silicone offers distinct advantages over conventional materials like glass, polycarbonate (PC), and PMMA (acrylic). Here’s a comparison highlighting why optical silicone is often the preferred choice:

| Feature | Optical Silicone | Glass | Polycarbonate (PC) & PMMA (Acrylic) |

|---|---|---|---|

| Flexibility/Durability | Excellent. Highly flexible, impact-resistant, non-shattering. | Poor. Brittle, shatters easily. | Good. More flexible than glass, but can crack under stress. |

| Weight | Very Low. Significantly lighter. | High. Much heavier. | Low. Lighter than glass, but generally heavier than silicone for similar strength. |

| Design Freedom | Excellent. Molds into complex, intricate shapes (e.g., integrated seals/lenses). | Limited. Difficult and costly for complex shapes. | Good. Moldable, but internal stresses can limit complexity or cause birefringence. |

| UV Resistance/Yellowing | Excellent. Highly resistant, non-yellowing over time. | Good. Generally stable, but can be heavy. | Poor. Prone to yellowing and degradation from UV exposure. |

| Thermal Stability | Excellent. Wide temperature range, resistant to thermal shock. | Good. High heat resistance, but sensitive to thermal shock. | Fair. Can deform or craze at higher temperatures. |

| Biocompatibility | Excellent. Often USP Class VI certified, suitable for medical contact. | N/A. Not typically used for direct biological contact in this context. | Poor. Generally not biocompatible for direct long-term biological contact. |

| Manufacturing Cost (Complex Parts) | Lower. Fewer post-molding steps (no polishing). | High. Requires grinding and polishing. | Moderate. Can require post-processing to reduce stress or improve clarity. |

| Transparency | Excellent. Very high light transmittance. | Excellent. Very high light transmittance. | Good. Can have good clarity but susceptible to yellowing over time. |

Key Optical Indices: Light Transmittance and Refractive Index

When evaluating any optical material, two fundamental properties are paramount: light transmittance and refractive index. For optical silicone, these indices are critically controlled during manufacturing to ensure optimal performance in diverse applications.

Light Transmittance

Light transmittance refers to the amount of light that passes through a material. It’s typically expressed as a percentage, indicating how “clear” or transparent the material is. Optical silicones are engineered for exceptionally high light transmittance, often achieving up to 94-95% in the visible light spectrum. This ensures minimal light loss and distortion as light travels through components like lenses, light guides, or encapsulants.

- Why it’s crucial: High transmittance directly translates to brighter, more efficient light output in LED applications and clearer images in sensor or display technologies. It ensures that the maximum amount of light generated or collected reaches its intended destination.

- Measurement Tools: Light transmittance is typically measured using specialized equipment such as a haze meter or a spectrophotometer. These instruments pass a light beam of a specific wavelength through the silicone sample and measure the intensity of the transmitted light.

- Relevant Standards: Standard test methods for measuring haze and luminous transmittance in transparent plastics (which include optical silicones) include ASTM D1003 and ISO 13468.

Refractive Index

The refractive index (RI) of a material describes how much light bends, or refracts, when it passes from one medium to another. It’s a dimensionless number, indicating the speed of light within the material relative to the speed of light in a vacuum. Optical silicones can be formulated to have a customizable refractive index, generally ranging from around 1.39 to 1.55, though specific formulations can push these boundaries.

- Why it’s crucial: The ability to tailor the refractive index is a powerful design tool. Engineers can precisely control how light is focused, diffused, or guided within an optical system. This flexibility enables the creation of more compact, efficient, and innovative optical designs, such as high-performance lenses or integrated light management systems.

- Measurement Tools: Refractive index is commonly measured using a refractometer, such as an Abbe refractometer. For higher precision or specialized applications, techniques involving optical interferometry or autocollimation may be employed.

- Relevant Standards: A standard test method for determining the refractive index of transparent organic plastics, which applies to optical silicones, is ASTM D542.

By meticulously controlling both light transmittance and refractive index through these advanced measurement tools and adherence to industry standards, manufacturers of optical silicone can offer highly specialized materials that meet the exact demands of cutting-edge optical technologies.

Chemistry of Optical Silicone

The remarkable properties of optical silicone, especially its light transmittance and refractive index (RI), are directly tied to its precise chemical composition.

Standard Optical Silicone (PDMS-Based)

Most common liquid silicone rubbers (LSRs) and standard optical silicones are based on polydimethylsiloxane (PDMS). This polymer forms the fundamental silicon-oxygen (Si-O) backbone, typically with methyl groups attached to the silicon atoms. PDMS-based silicones are known for their inherent high transparency and thermal stability. A pure PDMS backbone typically yields a refractive index around 1.41. For materials used in optical applications, fumed silica (a highly dispersed, non-reactive form of silicon dioxide) can be incorporated. This enhances mechanical strength while largely preserving optical clarity.

Phenylsiloxane-Based Optical Silicone (High Refractive Index)

To achieve a refractive index significantly higher than 1.41, specific chemical modifications are necessary. This is where phenylsiloxane-based silicones become crucial.

The introduction of phenyl groups (containing benzene rings) into the silicone polymer’s molecular structure is the primary method to increase RI. Phenyl groups are larger and more polarizable than methyl groups. This leads to higher material density and greater interaction with light. Consequently, phenyl-containing silicones can achieve RIs ranging from 1.46 to over 1.55.

Key characteristics of phenylsiloxane-based silicones include:

- Higher Refractive Index: This is their most notable feature for optical uses.

- Enhanced Thermal Stability: Phenyl groups improve resistance to high temperatures and oxidative degradation.

- Improved Low-Temperature Flexibility: They can help maintain elasticity even at very low temperatures.

- Radiation Resistance: These silicones offer better resistance to high-energy radiation like gamma rays.

- Optical Clarity and Non-Yellowing: Despite aromatic rings, they maintain excellent transparency and resist yellowing over time, even under heat or UV exposure.

- Mechanical Property Enhancement: Some formulations may show improved tensile or tear strength.

These high-refractive-index materials are often formulated as phenyl-containing silicone resins or phenyl-modified liquid silicone rubbers (LSRs). By precisely controlling the types and amounts of these chemical components, manufacturers can custom-tailor optical silicone to meet specific performance needs, balancing properties like RI, transparency, flexibility, and mechanical strength.

Conclusion

Optical silicone is clearly transforming the optics industry. Its unique blend of high light transmittance, tunable refractive index, and exceptional durability sets it apart. These properties, rooted in its sophisticated chemistry—from PDMS bases to advanced phenylsiloxane modifications—allow it to outperform traditional materials like glass and plastics.

This versatile material offers significant advantages. It provides superior flexibility, impact resistance, and environmental stability. These benefits make it indispensable across a wide range of applications. You’ll find it in cutting-edge LED lighting, advanced automotive systems, critical medical devices, and emerging AR/VR technologies.

As optical demands continue to grow, optical silicone will remain a vital component. Its ongoing development ensures it’s at the forefront of creating innovative, high-performance solutions for the future of optics.