Understanding Silicone Rubber

What is silicone rubber:

Definition: Silicone rubber is a type of polymer materials, its backbone consists of siloxane bonds (Si-O)

Importance: Rubber and plastics are two very important polymer materials that play a significant role in industry and daily life. Natural rubber and synthetic rubber are two main categories of rubber. Silicone rubber is a important branch of important branch of synthetic rubber. Therefore: Silicone rubber<Rubber

Key characteristics

- High and Low-Temperature Resistance: Wide operating temperature range (-60°C to 250°C).

- Weather Resistance: Excellent resistance to UV radiation and aging.

- Electrical Insulation: Superior electrical insulation properties.

- Biocompatibility: Suitable for medical and food-grade applications.

- Chemical Stability: Resistant to acids, alkalis, solvents, and other chemicals.

Types of Silicone Rubber/By form and by processing

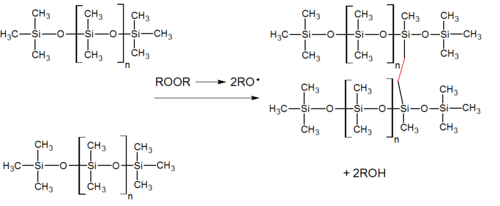

HCR/High Consistency Rubber/Solid Silicone: high-viscosity, gum-based silicone elastomer that requires curing to achieve its final properties. It is commonly processed through compression molding, transfer molding, or extrusion, followed by heat curing.

RTV Silicone/Room-Temperature Vulcanizing Silicone: RTV silicone is a liquid or paste-like silicone elastomer that cures at room temperature without requiring high heat. It is typically used for sealing, bonding, coating, and molding applications.

LSR/Liquid Silicone for injection molding: Liquid Silicone Rubber (LSR) is a two-part, platinum-cured silicone elastomer designed for high-precision injection molding. It offers excellent flowability, fast curing, and consistent mechanical properties, making it ideal for mass production of intricate silicone parts.

HTV (High-Temperature Vulcanizing) Silicone: is a high-consistency, heat-cured elastomer that requires high-temperature vulcanization to achieve its final properties. It is typically processed through compression molding, transfer molding, or extrusion, followed by heat curing using peroxide or platinum catalysts.

Conclusion: The definitions of silicone cross, such as one potting material, it can be a Liquid Silicone , and Room-Temperature Vulcanizing. And the other potting material, can be a Liquid Silicone, and High-Temperature Vulcanizing.

But silicone for injection molding, compression molding and extrusion is always HTV.

Silicone for casting(pouring), the definitions cross.

Factors to Consider When Choosing Silicone Rubber

Budget: Give the same technical index: tensile strength, tear strength. etc, LSR will cost more than solid silicone by weight. Besides the material cost, the tooling cost of liquid silicone (injection mold) is more expensive than that of solid silicone (compression mold)

Appearance: Liquid silicone offers better looking. Surface of LSR products is sensed more softer and smoother. And the spliter line(cause by two-plates mold) is less evident than solid silicone products.

Precision: Due to nature of low viscosity, automated processing, uniform mixing of liquid silicone, liquid silicone offers higher precision than solid silicone. Some high-value and high precision silicone products need to be achieved by liquid silicone injection molding.

Extrusion: Prevailing production is to extruded silicone using solid silicone. Liquid silicone takes less share in extrusion market.

Choosing Right Silicone Rubber Regarding the Application

Below is a base frame to help you choose your silicone rubber

| Application | Silicone Rubber | Features | Our Model |

| Home | RTV for Casting | FDA certified | GA-88XX |

| Food Grade Solid Silicone | FDA certified | GA-33XX | |

| Food Grade Liquid Silicone | FDA certified | GA-29XX | |

| Automobile | Precipitated Solid Silicone | Long Product Life | GA-11XX |

| Fumed Solid Silicone | Low VOC | GA-32XX | |

| Oil Bleeding Liquid Sicone | Low Friction | GA-20XX | |

| Flame Retardant Liquid Silicone | Resistant to fire | GA9600-XX | |

| Electronics | Self Adhesive Liquid Silicone | Primerless & Low Defect Rate | GA-72XX |

| Medical | General Medical Solid Silicone | Pass ISO 10993 | GA-TYXX |

| General Medical Liquid Silicone | Pass ISO 10993 | GA-65XX | |

| Medical Silicone for Implantation | Long time Implantation | No recommendation, recommended Newsil and Elkem branded | |

| Optical | Typical RI 1.41 | Regular High Tranparancy | CAS-35XX |

| Higher RI 1.46 for Injection Molding | Higher RI for Injection Molding | CAS-TAXX | |

| RI 1.51 for high end LED encapsulation | Low viscosity for easy dispensing and molding | CAS-TDXX | |

| Textile Coating | Liquid Silicone Coating for Glassfiber and Other Textile | Scratch-resistant, strong adhesion | GA-20X1 |

| Silicone Foam | Liquid Foam Silicone | Flame-Retardant, Customzied Shape | GA-FXX |