General Information

Synthetic Silicone Leather is a durable, eco-friendly material made from silicone and a synthetic fabric backing, designed to mimic natural leather with added resistance to wear, water, UV, and heat.

Features

| Feature | Silicone Leather | Genuine Leather | Conventional Synthetic Leather |

|---|---|---|---|

| Material Origin | Synthetic (silicone) | Animal hide | Synthetic (PU/PVC) |

| Durability | High | Medium-High (with care) | Low-Medium |

| Maintenance | Low | High | Low |

| Sustainability | Eco-friendly | Resource-intensive | Not eco-friendly |

| Aesthetic Appeal | Customizable | Natural, premium | Artificial-looking |

| Cost | Moderate | High | Low |

| Applications | Automotive, furniture | Luxury goods, upholstery | Budget items, fast fashion |

Material and Production Achieve Quality

Easy clean

Material Advantage

- Hydrophobic Nature: Silicone inherently repels water and other liquids

- Non-Porous Surface: Silicone leather’s surface is smooth and non-porous

- Chemical Resistance: Silicone resists most chemicals, oils, and solvents

Processing Advantage

- Surface Optimization: Hot-press rollers add textures for better hydrophobicity.

- Coating: Layer coatings create a low-friction, protective film.

- Additives: Molds and agents enhance anti-fouling properties.

- Curing: Heat and UV strengthen and smooth the surface.

- Post-Treatment: Sprays and polishing improve resistance and smoothness.

Long Durability

Material Advantage

- Chemical Stability: Silicone’s siloxane backbone provides exceptional resistance to UV radiation, oxygen, and temperature extremes.

- Elasticity: Silicone is naturally flexible and resistant to cracking, tearing, and deformation.

Processing Advantage

- Layer Coatings: Precision layers and curing bond and densify the material.

- High-Temperature Curing: Strengthens structure, improving tensile and tear resistance.

Anti-scratch

Material Advantage

- Surface Hardness: Silicone can be engineered with enhanced surface hardness to resist physical abrasions.

- Additives: Anti-scratch agents can be included in the silicone formulation to increase scratch resistance.

Processing Advantage

- Surface Treatments: A specialized coating or treatment during production creates a hard, protective top layer that minimizes abrasions.

- Hot-Pressing Technique: The silicone surface undergoes precise texturing to reduce the visibility of minor scratches.

Market

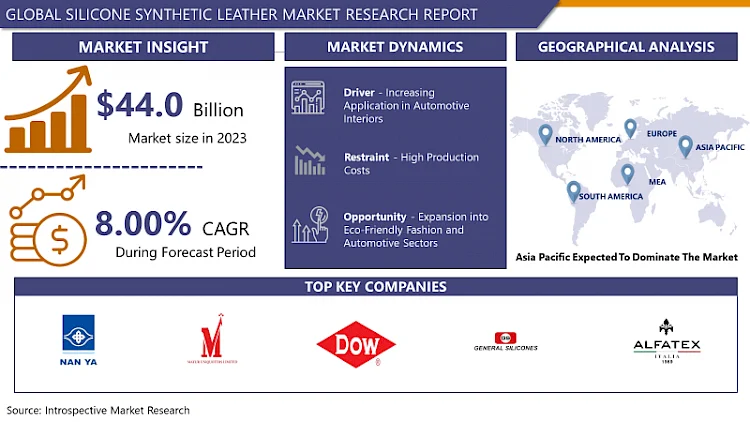

The silicone synthetic leather market is growing rapidly, valued at $44B in 2023 and projected to reach $87.95B by 2032 (8% CAGR). Growth is driven by environmental regulations, eco-friendly preferences, and demand from industries like automotive, fashion, and furniture. Asia-Pacific dominates due to industrial growth and sustainability trends.

Manufaturing/Processing

Material

- Base layer: Polyester fabric, cotton fabric, nylon fabric, blended fabrics, non-woven fabrics, polypropylene fibers etc.

- Silicone layers: Liquid Silicone Rubber

- Primer: Bonding silicone to base layer

- Surface treatment material

Material Preparation

- Selecting an appropriate base material

- Mix liquid silicone rubber evenly

- Priming process:Primer is applied to the substrate surface to improve adhesion

Silicone Coating (To apply the silicone to fabric)

- Applying silicone evenly onto the surface of the base material to achieve the desired coating thickness.

Hot Pressing (Form surface pattern)

- Using a hot pressing roller with a specific pattern to press the coated silicone and form the required surface texture.

- Curing the pressed material to solidify the silicone coating and enhance its physical properties.

Surface treatment

- Applying anti-fouling coatings

- Polishing to improved smothness

Application:

Silicone Leather is a versatile and high-performance material used in various industries due to its durability, eco-friendliness, and resistance to environmental factors. Some specific applications of silicone leather include:

- Upholstery and Furniture:

Silicone leather is commonly used for upholstery in furniture, offering excellent resistance to stains, water, and abrasion. It is easy to clean and maintain, making it ideal for high-traffic environments such as offices, hotels, and healthcare facilities. - Automotive Interiors:

Due to its heat resistance, UV stability, and flexibility, silicone leather is an excellent choice for automotive interiors, including seats, dashboards, and door panels. It remains soft and durable even under extreme temperature fluctuations. - Fashion and Accessories:

Silicone leather is used in fashion items like bags, wallets, and shoes. It is lightweight, hypoallergenic, and available in various textures and finishes, making it a sustainable alternative to natural leather. - Marine and Outdoor Applications:

Its waterproof and UV-resistant properties make silicone leather suitable for outdoor furniture, boat seats, and other marine applications. It withstands prolonged exposure to sunlight and saltwater without deteriorating. - Medical and Healthcare:

Silicone leather is a hygienic material often used in medical furniture and devices. It is non-toxic, easy to sterilize, and resistant to microbial growth, meeting strict healthcare standards. - Environmental Sustainability:

Silicone leather is free from PVC, solvents, and other harmful chemicals, making it an eco-friendly option. Its long lifespan and recyclability contribute to reducing environmental impact.

Product Base

Contact me for more silicone leather products