General Information

Oil Bleeding Liquid Silicone Rubber (LSR) refers to a type of liquid silicone rubber that is specially formulated to release or “bleed” silicone oil onto its surface over time. This property is achieved by incorporating low-molecular-weight silicone oil into the silicone rubber matrix, allowing it to migrate to the surface gradually.

The formula :

The formula

Total Oil Content = Oil Bleeding Rate × Oil Bleeding Time

Oil Bleeding Rate is the key factors when using bleeding oil for production.

Key features that control Stable Oil Bleeding Rate

- Component Ratios: Precise proportions ensure stable oil bleeding.

- Phenyl Silicone Oil: Improves compatibility for controlled migration.

- Diatomaceous Earth: Enhances structure and uniform bleeding.

Oil Bleeding Time

Product oil silicone can endure up to 12 months

Example

Dynamic Industrial Seals

- High-Viscosity Silicone Oil: Provides slow and steady migration, ensuring long-term lubrication without frequent maintenance.

- Non-Volatile Silicone Oil: Maintains stability and functionality in high-friction and high-temperature environments.

- Moderate Bleeding Rate: Balances consistent lubrication with minimal risk of over-oiling, preventing contamination of surrounding components.

- Industrial-Grade Material: Engineered for durability and resistance to harsh chemicals, making it suitable for heavy-duty applications.

Dynamic Industrial Seals

- Low-Viscosity Silicone Oil: For quick lubrication, reducing friction effectively during insertion.

- Non-Volatile Silicone Oil: To provide stable lubrication and avoid evaporation risks.

- Moderate Bleeding Rate: To ensure adequate lubrication without over-lubricating.

- Medical-Grade Material: To ensure biocompatibility and safety for use in medical devices.

Classifications

| Classification Basis | Type | Characteristics | Applications |

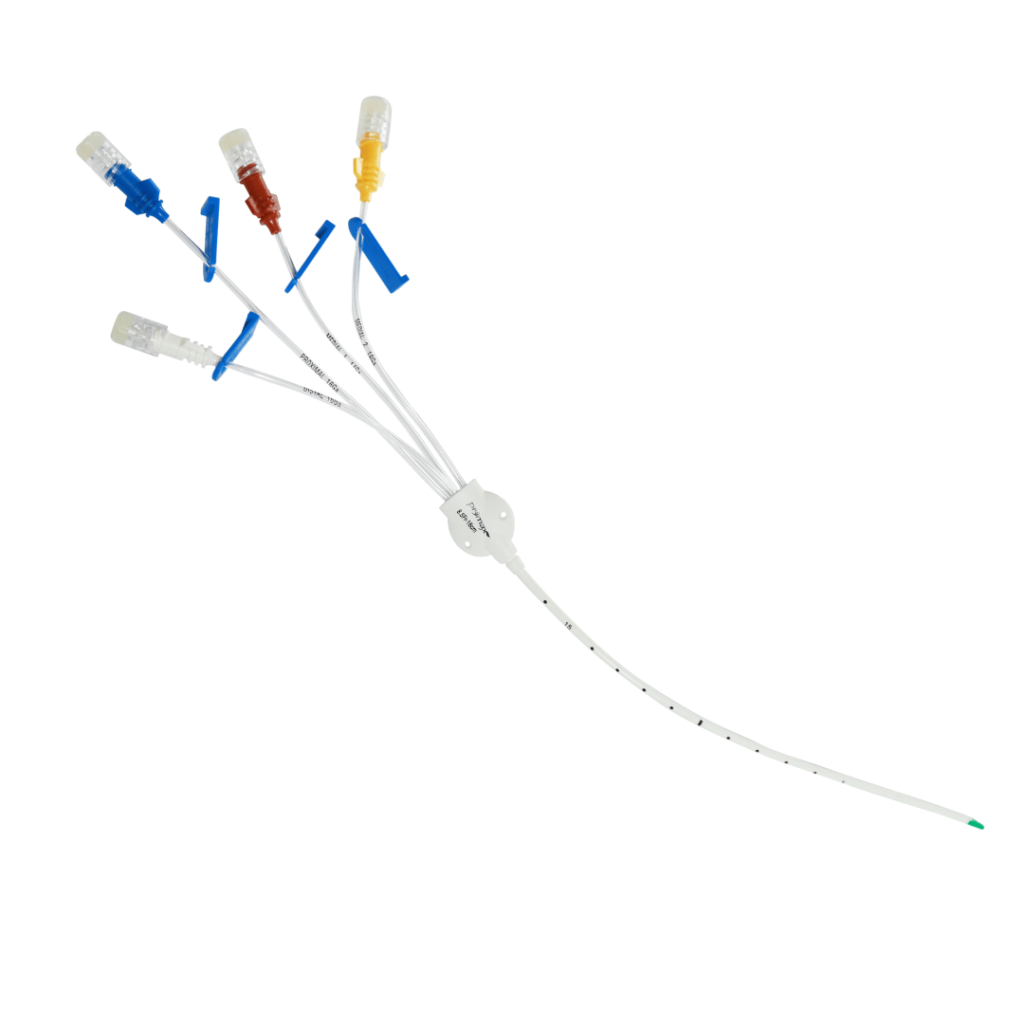

| Silicone Oil Viscosity | Low-Viscosity Silicone Oil | Fast migration rate, high lubricity, short-lasting | Disposable products (e.g., medical catheters, pads); quick-lubrication needs (e.g., adult toys, cosmetic tools) |

| Medium-Viscosity Silicone Oil | Moderate migration rate, stable lubricating effect, longer lifespan | Industrial seals; components requiring long-term lubrication | |

| High-Viscosity Silicone Oil | Slow and even oil migration, surface remains less greasy | Medical devices (e.g., implants); premium consumer goods (e.g., high-end makeup brush handles) | |

| Silicone Oil Type | Volatile Silicone Oil (e.g., D4, D5, D6) | Provides lubrication in a short time, fast migration, highly volatile | Anti-stick packaging; single-use medical devices |

| Non-Volatile Silicone Oil (e.g., High Molecular Weight PDMS) | High stability, low volatility, suitable for long-term use | Long-term medical products; industrial seals in high-temperature environments | |

| Modified Silicone Oil | Functionalized (e.g., waterproof, anti-static, conductive) | High-end electronics protection; waterproof consumer goods (e.g., phone cases) | |

| Oil Bleeding Rate | High Oil-Bleeding Silicone | Large oil migration, continuous surface lubrication | Medical devices (e.g., urinary catheters); anti-friction patches |

| Medium Oil-Bleeding Silicone | Moderate migration, suitable for stable long-term use | Industrial components (e.g., dynamic seals); consumer goods (e.g., makeup brush handles) | |

| Low Oil-Bleeding Silicone | Slow migration, surface remains less greasy | Long-term protection scenarios (e.g., electronic components); luxury accessories | |

| Application Field | Medical-Grade Oil-Bleeding Silicone | High purity, biocompatible PDMS | Catheters, seals, surface treatment for artificial organs |

| Industrial-Grade Oil-Bleeding Silicone | Chemically resistant modified silicone oil or high-viscosity PDMS | Dynamic seals, lubricating gaskets, chemical-resistant components | |

| Consumer-Grade Oil-Bleeding Silicone | Medium viscosity, low-volatility PDMS | Cosmetic tools, adult toys, anti-slip mats |