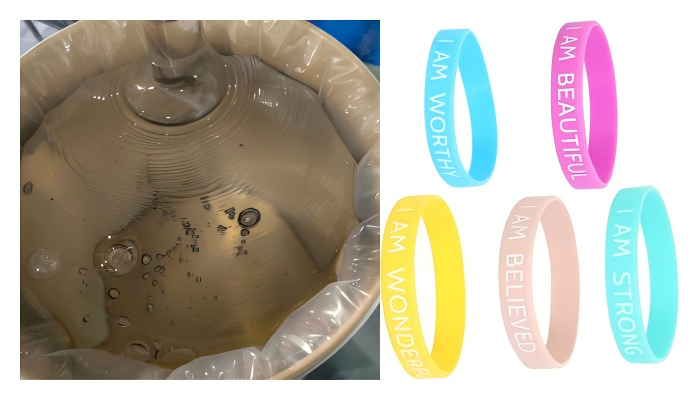

Trademark Silicone Rubber material, also referred to as label glue or heat transfer silicone, is used to create silicone-based labels or logos. Unlike traditional textile trademarks, this material involves injecting silicone rubber into a mold designed with the label or logo pattern. The mold is then pressed onto the surface of the original trademark paper, and after the molding process, the mold is separated from the paper, leaving behind the silicone rubber label.

The silicone rubber itself is highly flexible and adhesive, making it ideal for attaching to clothing. Unlike other types of labels, which can feel rigid or uncomfortable, silicone rubber labels remain soft and flexible, offering a comfortable wearing experience. The process for producing these labels can include heat transfer, printing, or dispensing, depending on the desired outcome. This versatile material is particularly well-suited for creating detailed and intricate patterns, offering both durability and flexibility for various clothing applications.

Types of Trade Mark Silicone Rubber

What is Heat Transfer Silicone Rubber Material Used For?

Heat transfer silicone rubber is a highly versatile material used across various industries to provide heat management and protection. It is a polymer material commonly utilized in automotive, aerospace, medical, and industrial sectors for its ability to transfer heat efficiently and protect components from high temperatures and environmental stress. This material also serves as a sealant, ensuring that joints are tightly sealed and leak-proof.

Made from a combination of silicone and other additives like rubber, glass, and carbon black, heat transfer silicone rubber is processed through curing to form sheets or molded shapes. It is highly valued for its exceptional heat transfer capabilities and its ability to resist UV radiation, high temperatures, and other environmental factors.

Heat transfer silicone rubber is a popular choice in heat-sensitive applications due to its flexibility and durability. The material’s ability to withstand extreme temperatures makes it ideal for use in applications that require both insulation and thermal management. It can be used in manufacturing, sealing joints, and protecting components in electronic, medical, and automotive products.

Key Applications:

- Automotive: Used for sealing and heat insulation in automotive parts

- Aerospace: Provides heat resistance and protection for aerospace components

- Medical: Used in medical devices where temperature control and protection are crucial

- Industrial: Applied in various industrial equipment that requires heat insulation and sealing properties

Various manufacturing processes, including injection molding, extrusion molding, and calendaring, are used to shape heat transfer silicone rubber. These techniques help produce complex shapes, simple parts, and thin layers, depending on the application.

The Benefits of Using Trademark Silicone Rubber

Trademark silicone rubber is a premium material widely used across multiple industries due to its broad range of desirable properties.

- Temperature Resistance: It withstands extreme temperatures from -100°C to 300°C without performance degradation, making it suitable for industries such as food, medical, and automotive technology.

- Environmental Resistance: It is highly resistant to UV radiation, ozone, and other environmental elements, making it perfect for outdoor applications.

- Water and Oil Resistance: Its resistance to water, oil, and chemicals makes it an ideal choice for waterproofing applications such as pumps and seals.

- Chemical Inertness: Non-toxic and chemically stable, trademark silicone rubber is perfect for medical and food-processing applications where contact with the body or food is required.

- Flexibility: This material can be easily molded into intricate shapes, making it ideal for precision manufacturing in industries such as medical devices and electronics.

- Durability: Known for its longevity, trademark silicone rubber maintains its performance over time, reducing the need for frequent replacements, which is essential in automotive and industrial applications.

Overall, trademark silicone rubber stands out due to its flexibility, environmental resistance, and ability to endure extreme conditions. It is an excellent material for a wide range of manufacturing and design applications, offering durability, safety, and flexibility for products across various sectors.