Classification Levels in ISO 10993:

- Low risk (Class I): Devices that have minimal interaction with the body, such as external surface contact devices (e.g., bandages).

- Medium risk (Class II): Devices with moderate biological risk, requiring more comprehensive testing, such as devices that are in contact with mucosal membranes (e.g., catheters).

- High risk (Class III): Devices that are implanted or have prolonged or permanent contact with the body, requiring extensive biocompatibility testing (e.g., heart valves, pacemakers).

Certification

- Vitro cytotoxicity

- Skin sensitization

- Irritation

- Interactions with blood

- Systemic toxicity

Types of medical grade silicone rubber

At Newsil, a leading manufacturer of medical-grade silicone, we are dedicated to providing top-quality silicone rubber and exceptional service. Our medical silicone materials are engineered to withstand high temperatures, resist abrasion, and offer corrosion resistance, ensuring safety, reliability, and long-lasting performance. Manufactured to the highest industry standards, our medical silicone undergoes rigorous testing for both safety and reliability. The material is non-toxic and hypoallergenic, making it safe for use in medical devices and other critical applications.

We take pride in being a trusted supplier of medical-grade silicone rubber to customers worldwide. Our team of experts is ready to assist you in selecting the perfect product for your needs, and we offer customized solutions tailored to your specific requirements.

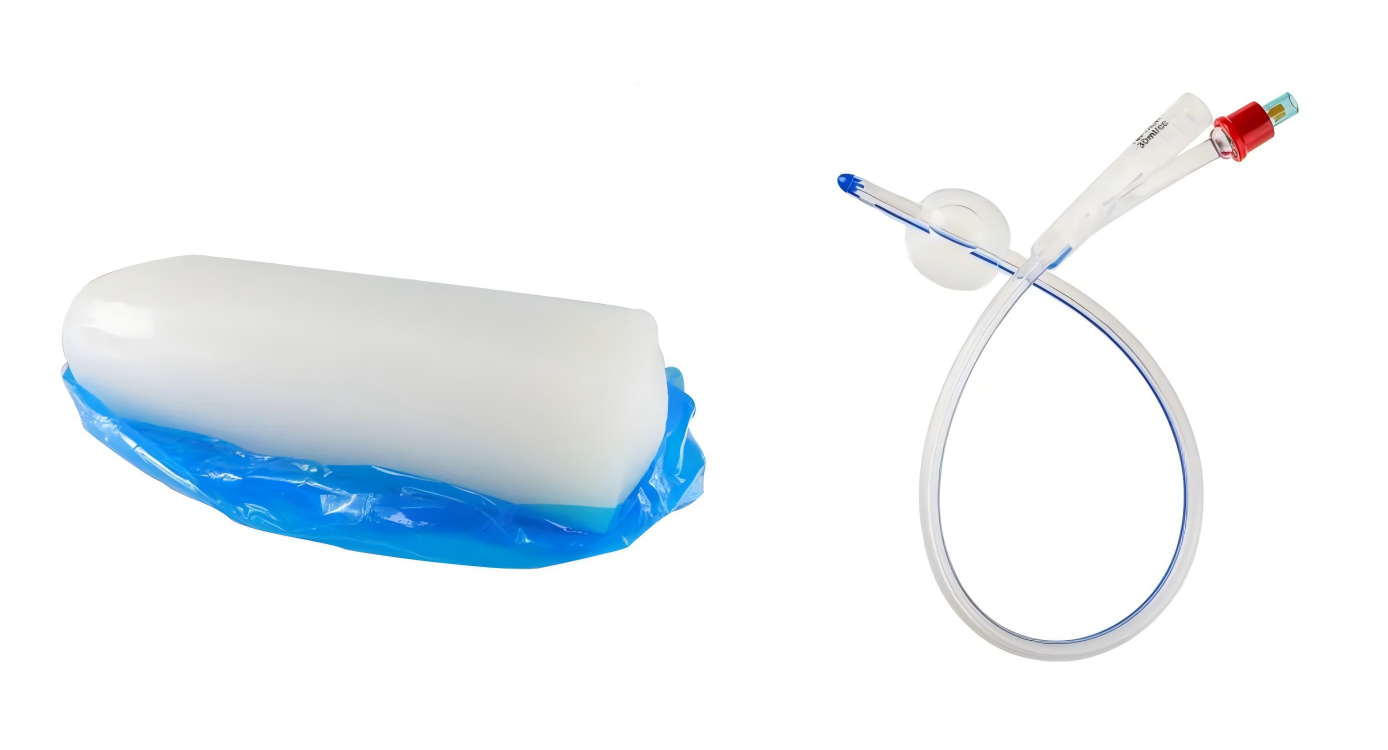

Explore a wide range of specialized medical-grade silicone rubber formulations, designed for precision and reliability in critical healthcare applications. Our Liquid Silicone Rubber for Catheter Cavities offers optimal performance and safety, ensuring the highest standards in medical applications. Our Medical Grade Silicone Rubber for Catheter Tubes is carefully engineered to meet rigorous healthcare regulations, providing durability and dependability. These advanced materials combine flexibility, biocompatibility, and resilience, redefining the capabilities of medical silicone rubber. Join us in a space where innovation enhances healthcare, with each formulation, from catheter cavities to tubes, meticulously crafted to improve medical device performance and patient safety.

Difference Between Silicone and Medical Silicone for Sale

The primary distinction between regular silicone and medical silicone lies in their composition and manufacturing processes. Standard silicone rubber products are made by blending ordinary silicone, while medical silicone rubber is a specialized synthetic elastomer developed and manufactured by medical silicone factories to meet rigorous regulatory standards. These standards ensure suitability for use in medical devices, implants, and other healthcare applications.

Medical-grade silicone undergoes extensive testing to guarantee biocompatibility, durability, and resistance to bacterial growth. It is produced with higher purity levels, fewer harmful substances, and more controlled manufacturing processes to minimize potential contaminants. This makes medical silicone suitable for prolonged contact with the human body without causing adverse reactions or complications.

In addition, medical silicone often requires specific certifications, such as ISO 10993 or USP Class VI, to validate its safety and reliability in medical settings. These certifications confirm that the material has undergone thorough testing and meets the essential biocompatibility and performance standards.

Looking for Silicone Rubber Medical Products? Newsil Can Help!

As a leading manufacturer of silicone rubber in China, Newsil proudly offers a broad range of medical silicone materials that adhere to the strict requirements of the medical industry. Our medical adhesive silicone rubber is ideal for various applications, including medical device components, sealing, gaskets, and more.

Silicone Rubber in Medical Applications

Medical-grade silicone is a type of polymer used in a variety of medical and industrial applications. It is crafted from a specialized formulation of silicone that has been rigorously tested and certified to meet safety and quality standards. This material is used in the production of various medical products, including syringes, catheters, implants, and contact lenses. Additionally, it is essential for manufacturing medical devices such as artificial heart valves, hearing aids, and prosthetics.

Medical-grade silicone is considered the safest and most effective material for medical products due to its biocompatibility, low risk of infection, and inflammation. It is non-toxic, non-reactive, and will not interact with other substances or cause adverse reactions in the body. Its excellent physical and chemical properties, such as durability and flexibility, make it ideal for a wide range of medical uses.

To ensure safety, the U.S. Food and Drug Administration (FDA) has established strict standards for medical silicone. All silicone products must meet these criteria to be classified as medical grade. These standards include testing for non-toxicity, chemical compatibility with other medical components, correct chemical composition, dimensions, and surface finish.

The process of creating medical-grade adhesive silicone is complex and involves multiple stages of testing and quality control. Raw materials are tested to ensure compliance with FDA criteria, and the silicone undergoes precise formulation, further testing, and inspection to guarantee that it meets all FDA standards.

Medical-grade silicone is crucial in numerous medical and healthcare applications, and its use is highly regulated by the FDA. As a trusted medical silicone supplier, Newsil ensures that our medical-grade silicone rubber is safe, reliable, and provides optimal performance for patients.

Advantages of Newsil Medical Silicone Rubber

Chemical Resistance: Newsil’s liquid silicone rubber is resistant to a variety of chemicals, ensuring stability when in contact with medications and bodily fluids, contributing to the longevity and reliability of medical devices.

Biocompatibility: Newsil Medical Silicone Rubber is biocompatible, ensuring it is well-tolerated by the human body, minimizing the risk of adverse reactions.

Versatility: Its versatility allows for the production of a wide range of medical applications, including implants, catheters, and seals, to meet diverse healthcare needs.

Flexibility and Elasticity: The superior flexibility and elasticity of our medical silicone enhance the comfort and functionality of medical devices, adapting to anatomical contours.

Durability: Newsil Medical Silicone Rubber is designed to withstand the demands of medical procedures, maintaining structural integrity over time.

Resistance to Sterilization: The material remains effective even after exposure to common sterilization methods, ensuring reliable sterilization of medical devices without compromising performance.

Customized Formulations: Newsil offers tailored silicone formulations to meet the specific requirements of diverse medical applications, providing precise solutions for various devices.

Excellent Sealing Properties: Our medical silicone rubber has excellent sealing capabilities, preventing the ingress of contaminants, making it ideal for applications where hygiene is critical.