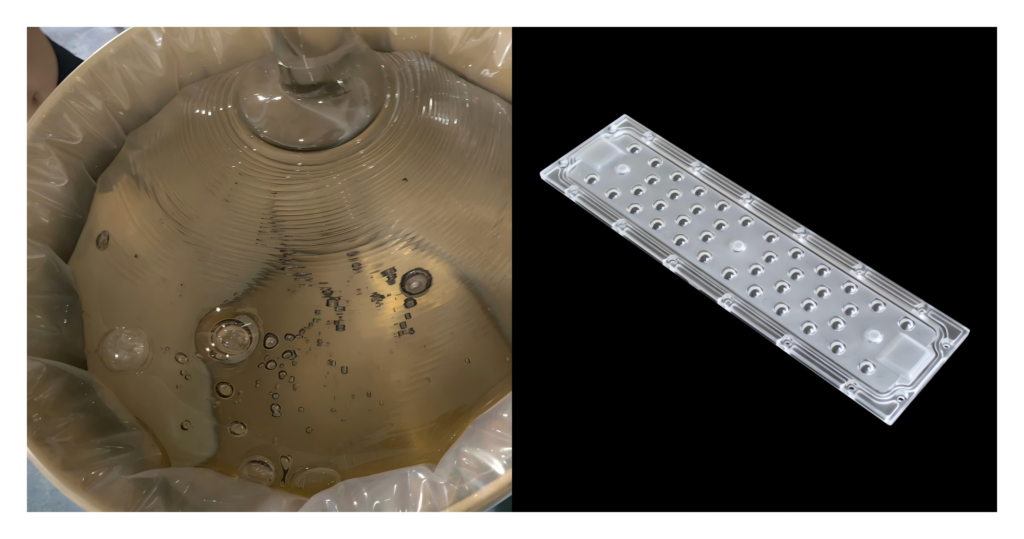

Optical LSR for Injection Molding is a high-performance material widely used in LED and CCTV applications due to its exceptional optical clarity, durability, and precision molding capabilities. In LED lighting, it is used for lenses, covers, and light guides, offering high light transmission, UV resistance, and thermal stability. For CCTV cameras, it is ideal for protective covers and lenses, providing scratch resistance, weatherproofing, and long-term clarity. Its flexibility, chemical resistance, and ability to be molded into complex shapes make it a preferred choice for high-quality optical components in these industries.

Features

- High optical clarity (excellent light transmission, low haze).

- Temperature resistance (-50°C to 200°C).

- UV and chemical resistance (long-term durability).

- Flexibility and tear resistance.

- Biocompatibility (for medical grades).

- Precision molding (low viscosity, complex designs).

- Scratch and weather resistance.

- Maintains transparency over time.

Applications

Applications of Optical LSR:

- LED lighting: Lenses, covers, light guides.

- CCTV cameras: Protective covers, lenses.

- Medical devices: Surgical instrument lenses, seals, tubing.

- Consumer electronics: Keypads, touchscreen components.

- Automotive: LED components, sensors.

- Industrial: Optical sensors, protective covers.

- Wearable devices: Transparent, flexible parts.

Technical Index

| Typical Properties | Value | Standard |

| Density | 1.13 | JIS K6268 |

| Appearance | Transparent | ASTM D2090 |

| Viscosity, Part A | 250000 mPas | ASTM D1084, D2196 |

| Viscosity, Part B | 300000 mPas | ASTM D1084, D2196 |

| Tensile Strength | 5.1 MPa | ASTM D412, D882 |

| Elongation | 270 | ASTM D412, D882 |

| Tear Strength | 15 kN/m | ASTM D624 |

| Refractive Index, 589 nm | 1.46 | ASTM D1747, D1218 |